Updated October 2022

Bamboo. It’s the prize jewel for so many sustainable fashion companies, the enemy of sustainability auditors, and the most confusing fabric for shoppers trying to do their damn best.

If it was 2016 and you asked me is bamboo fabric sustainable? I would have said “yes” and proudly flaunted my bamboo dress. Nowadays, I stay away from it and softly interrogate anyone who says they produce sustainable bamboo clothing.

After beginning my research in 2017, engaging in conversations with an incredible international sustainability auditor and bamboo fabric expert, and completing some serious sleuthing, I am here to update you on the facts around bamboo and try my best to answer if bamboo is, in fact, a sustainable fabric.

LET’S START WITH WHAT WE KNOW ABOUT BAMBOO

Bamboo is a super plant.

If the next Avengers movie stars ‘Bamboo Man’, I wouldn’t be surprised. Bamboo is often labeled ‘the world’s most renewable material’ and is the fastest-growing woody plant in the world. It can grow up to four feet in one day, no joke. The panda’s kryptonite absorbs five times more carbon dioxide and produces 35% more oxygen than a similar group of trees.

To thrive like this, bamboo requires no pesticides and little water; especially compared to cotton crops.

When bamboo is harvested, the plant regenerates itself in a flash (see, a superhero in the making!). A panda would also tell you it’s delicious, and I could go on to talk about its erosion reducing and soil nourishing qualities, but you get the idea.

After reading the lush qualities above, you can understand how bamboo could so easily fall into the sustainable fabric category without a blink of an eye. But there’s more to bamboo fabric than the origins of its materials.

Before we launch into the good stuff, you may have heard the words rayon, lyocell, TENCEL, modal, and viscose thrown around in your search to discover the truth about bamboo. These words are often used interchangeably, confusing readers and consumers, ultimately making the ‘sustainable bamboo’ topic even more difficult to wade through.

Image via Unsplash

DEFINITIONS

Rayon: The general term for regenerated cellulose fibers. Rayon is considered a semi-synthetic material as the cellulose fibers are natural but always broken down using chemicals.

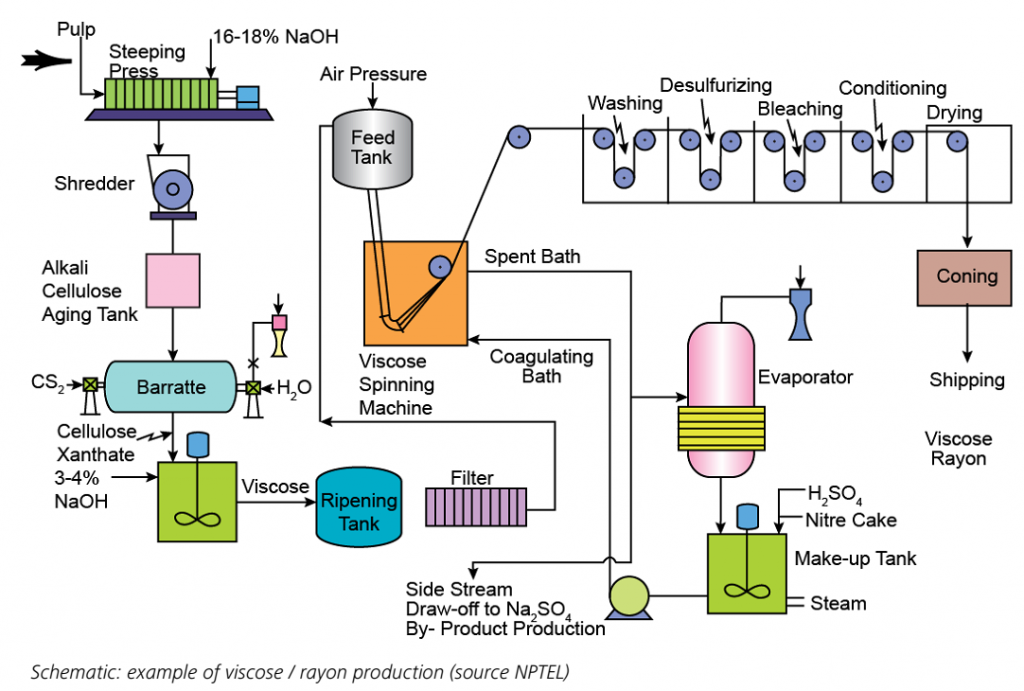

Viscose: Regenerated cellulose fiber made from wood pulp or plants using the viscose process. The wood pulp is treated with chemicals, filtered, and then spun into thread.

Modal: A stronger version of viscose. Modal is often blended with other textiles, such as cotton and spandex, to make it even stronger.

Lyocell: Similar to viscose and modal, but it is made using a different solvent. Lyocell is produced in a solvent-spinning technique called dry jet-wet spinning.

TENCEL: The branded version of lyocell and modal. TENCEL is often considered the most sustainable way to produce cellulose fiber-based fabrics. It focuses on closed-loop production and using less resource-intensive processes.

95% of the bamboo on the market is bamboo viscose.

You can also find bamboo rayon, bamboo lyocell, bamboo TENCEL, bamboo modal, and bamboo viscose. Bamboo linen is another form of bamboo fabric to add to the mix, produced mechanically and without chemicals. However, because the fabric is very labour intensive, expensive, and does not result in a soft fabric like bamboo viscose, it is incredibly rare

Image via Textile School

The issue with bamboo

Harsh chemicals

For bamboo to be turned into bamboo viscose, cellulose is extracted from the plant through the use of harsh chemicals.

It is then fed through a spinneret so the strands can solidify to make a fibre. Among the chemicals used in this process are sodium hydroxide, sulfuric acid, and carbon disulfide.

These chemicals are incredibly harmful to living creatures and the environment. The use of chemicals in factories affects factory workers, pollutes the air, and infects nearby water systems. I don’t know about you, but I wouldn’t warrant this just so I could have plush bamboo underwear!

To make things worse, depending on the factory, chemicals such as carbon di-sulphate and zinc sulphate are released as bi-products during the viscose process. Both these chemicals are highly toxic to water-based organisms. If the chemicals are not disposed of as hazardous waste, they’re washed away into water systems.

Mono plantations

Bamboo is generally grown and harvested in mono plantations. Mono plantations mean only one type of plant, bamboo in the case, is planted in one area. Often forests and established ecosystems are removed to make way for mono plantations, and biodiversity is decreased. Plantlife, animals, insects, and the general ecosystem become more susceptible to disease, have access to less food, and the environment is usually stark and barren.

The bamboo is produced in a closed-loop system. Is that okay?

Unfortunately, even when bamboo fabric is produced in a closed-loop system, there will always be toxic waste. If the company is able to provide evidence that the toxic waste is disposed of responsibly, that is great. If they blatantly deny that any waste is produced and claim to be 100% closed loop, that is really suspicious. I would personally walk away.

But my bamboo clothes are OEKOTEX Standard approved!

The OEKOTEX Standard is good for our bodies as it ensures there are no chemicals left in the garment when complete, and therefore no chemicals come into contact with our skin when we wear the clothes.

Yet, OEKOTEX does not refer to the chemicals used during the production process or ensures they were disposed of responsibly.

In a nutshell, OEKOTEX ensures clothes are safe for the humans who wear them, but not for the environment or anyone else involved in the making of the garment.

FINAL RECOMMENDATIONS

For now, we can choose bamboo linen when possible, and ask brands using bamboo TENCEL about their water treatment, hazardous waste facilities, and plantations.

This bamboo investigation has taught me that are endless layers to everything, the landscape is constantly changing and it’s almost impossible to keep up. Regardless of the complexity, it is so important to understand our clothes from seed to garment; staying ignorant isn’t an option anymore. Shop wisely.

A quick note:

This article may contain information that was accurate at the time of publishing, but things change. Brands evolve, certifications and their status can change, and links occasionally break. We do our best to keep everything up to date, but if you spot something that needs a refresh, feel free to let us know.